Flexible Rubber Bellows: An Overview, Working, and Applications Discussed

Flexible rubber bellows are used in applications where protection or isolation of moving parts is required. These flexible rubber bellows are also known as expansion joints in some applications. Industrial rubber bellows are manufactured by using different materials and methods of manufacturing, so it is essential to know what performance metrics they need to achieve, how they will operate in the real world, and what applications each option is suitable for. In this post we will address these concepts and more.

Introduction to Industrial Rubber Bellows

The primary purpose of utilizing a bellows is to prevent unwanted contact and/or contaminates from entering mechanical linkages. They can also keep lubricants where they need to be or even help with pressure regulation. There are also cases where something that looks like a bellows may actually be acting like an air intake or fluid transfer tube. This is just to point out that there are as many different uses for a durable bellows as there are material and size options.

Let us discuss how exactly the flexible rubber bellows work in an industrial set up.

Working/Movements of Industrial Rubber Bellows

Here we will discuss some common movement scenarios in industrial applications and how a bellows can help.

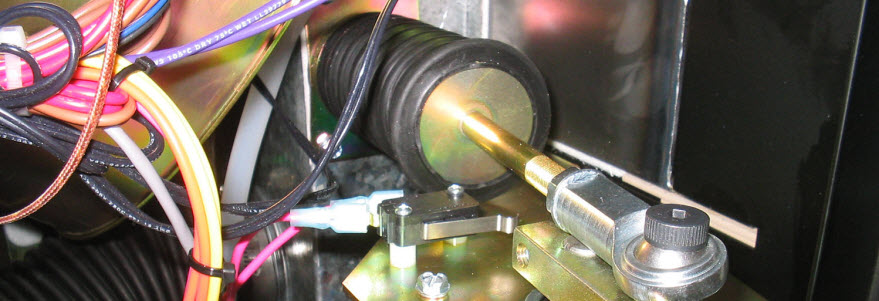

1.Linear Movement: Pistons, actuators, ball screws, and jacks are just a few examples of expanding linear joints. In a car engine there is not need to cover a piston. It would certainly make the engine malfunction. However, there are many times that a piston can use covering because it’s exposed to the environment. Ensuring ease of motion that is consistent with the strength of the movement is critical. Choosing a material that is too thick or stiff, which may provide outstanding wear protection, may negatively affect the linear motion itself.

2.Lateral Movement: The linkages and pipes are exposed to lateral movement as a result of shear stress. The shear stress may be applied on the linkages due to the weight of mounted equipment, external impact, etc. The flexible rubber bellows are used to protect parts and minimize stress during lateral movement and bending. In these instances, the bellows acts as a buffer as much as a cover.

3.Angular Movement: Flexing joints are “pinch points” where fingers or equipment can get caught and damaged. Bellows can help with that as well as protection from debris and impact. Often there is some amount of movement along either axis during an angular bend and the bellows can better accommodate that movement than a fixed-length sleeve or tube.

4.Torsional Movement: This is when the mechanical linkages are exposed to rotary or torsional movement during operation. Since a bellows can absorb linear, shear, and angular forces, it can accommodate complex movement and help reduce system stress. Depending on design, you can use a bellows to reduce torsional speed or limit rotation, or allow for as free a movement as possible. There are limits on the rotation of the bellows if it is fixed at both ends since it will tend to turn into a spring and deform if too much rotational stress is placed on it. This type of movement provides the most challenges to getting a proper bellows, but there are options.

In conclusion, bellows solve problems in moving industrial systems, but they are only as reliable as the company that makes them. Choosing an ISO9001 registered manufacturer like Crushproof Tubing Co ensures that you get the highest quality materials and service to back it up.