- Home

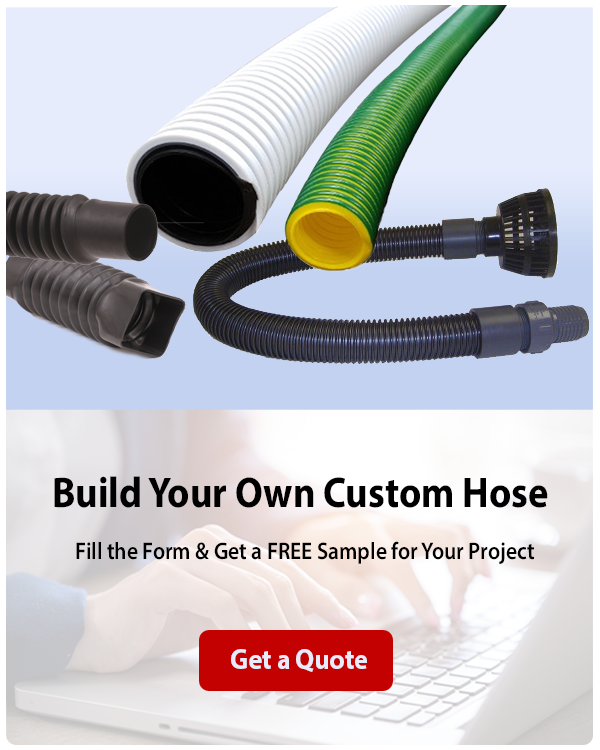

- Custom OEM Hose

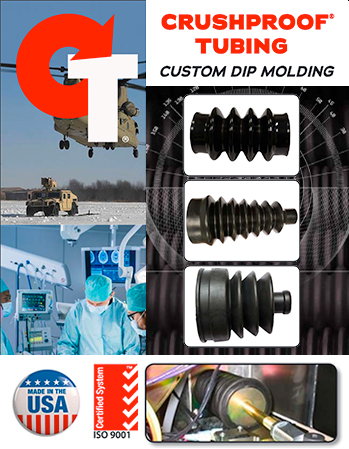

- Dip Molding

Dip Molding Process Bellows

Benefits of Dip Molding

Dip molding has grown into a popular manufacturing method over the last few years. The process is relatively inexpensive and is a simple and highly effective way to make specialized parts because it is a versatile and reliable method that requires minimal tooling. The other benefits of the process include:

- Dip molding has low setup costs and does not require secondary processing.

- The process creates high quality parts with a smooth, polished looking finish.

- This manufacturing process can produce components with a seamless surface.

- Due to the uniqueness and flexibility of the dip molding process, parts can be easily made longer or shorter, thicker or thinner as per the customers’ requirements.

- Lead times for dip molding tooling is substantially less compared to other plastic manufacturing process. Production parts can be ready in as little as 30 days.

- The process can produce quick and inexpensive prototypes including bellows, boots, and covers, among others.

- The process can deliver custom solutions quickly and effectively and offers myriad material hardness, texture, and color options.

Why Choose Crushproof® Tubing to Make Dip Molded Parts

Crushproof® Tubing possesses the capabilities to meet your unique requirements for small and medium sized runs of dip molded parts. Depending on the part requirements, we may be able to use our tooling-free processes as well. Visit our Build-A-Hose page to request custom sample and we’ll get started making it to your specifications! As a solutions company, our goal is to utilize all our production capabilities to solve your unique design challenge at the best overall value for you. Our key differentiators are:

- In-house, no charge CAD design to make sure your parts look right the first time.

- Quick tooling turnaround from a trusted local supplier.

- Low cost tooling.

- Parts can be sampled within a few days of tooling completion, so you won’t find a faster turnaround time.

- We specialize in small and medium runs, so we won’t turn you away because you don’t need a million units.

- We are experts in creating custom parts from your ideas or drawings while maintaining low production costs.

Applications of Dip Molded Parts

The applications for dip molded parts are almost endless. From industrial boots and covers to medical dip molding to consumer goods, they can be found just about everywhere due to their cost effectiveness and performance. Dip molded parts are popularly used across automotive, electronics, pharmaceutical, food processing, construction, energy, semiconductor, medical industries among several others. A few examples of parts that are commonly manufactured utilizing the technique include:

- Dust boots and bellows

- Caps and plugs

- Gloves

- Socket holders

- Automotive interior components

- Electrical components

- Electrical masks

- End caps

- Gas pump handles

- Grips

- Hole plugs

- Probe covers

- Seat belt anchors

- Tool handles

Manufactured for maximum strength and durability, custom medical dip molding bellows or other components can be produced cost-effectively at an volume. At Crushproof Tubing, we have created thousands of custom parts as per the customer’s budget, timeline, standard requirements and delivery preferences. From concept to prototype and through production, we solve your design challenges quickly and effectively. Call us at 800-654-6858 to speak with an expert and learn more about our prototype development and dip-molding capabilities.